Facility for the investigation and certification of low-speed fans for HVAC systems in the automotive, aeronautical and building sectors and for domestic appliances. The ALCOVES facility has been designed for research and certification of low-speed cooling fans and small compressors. It consists in two rooms separated by a wall partition that can host a cooling fan system such as used in the automotive sector (including the motor, stator, rotor and heat exchanger) of up to 0.8 m diameter. The upstream room is anechoic down to 150 Hz as per the ISO 3745 norm. The downstream room is acoustically treated as well and leads, via an acoustic muffler and a network of pipes equipped with mass flow measurement devices, to an auxiliary fan that permits adjusting the operating point of the test component. The specific asset of this facility is thus its ability to measure the noise power and directivity of a fan system operated at controlled operating points, simultaneously with an accurate measurement of this operating point. The measured aerodynamic performance data include the volumetric flow rate, pressure rise, electric power consumption as well as torque, from which the fan performance and efficiency can be derived.

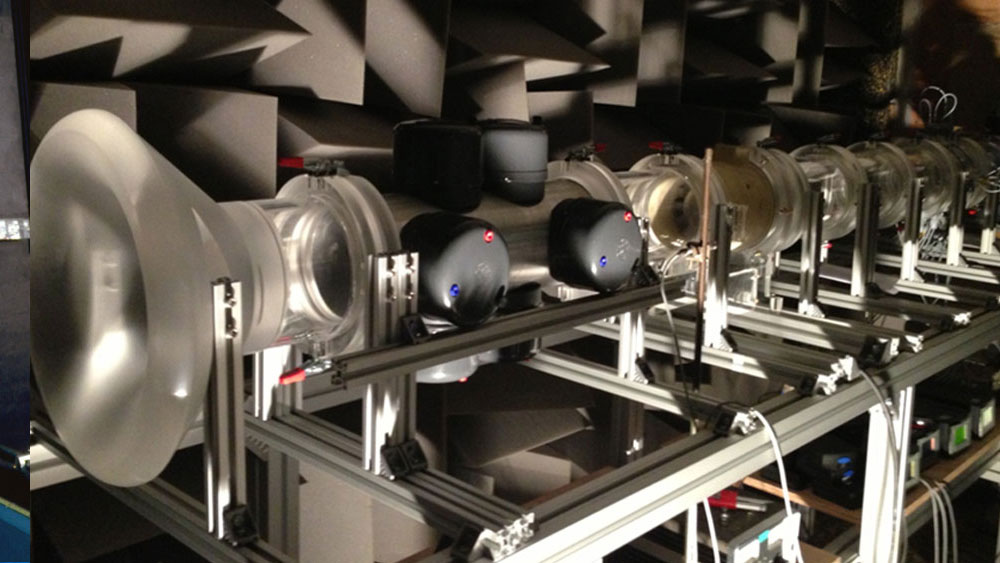

The facility can also host an acoustic multiport test bench that was specifically developed for the investigation and certification of ducted fan systems. The fan is placed in a duct equipped with multiple microphone and loudspeaker arrays that are used following a procedure permitting to decontaminate the microphone measurements from the inevitable reflections at the duct ends and scattering by the test component itself. The true active power of the fan can thus be obtained. The system has been designed for the investigation of so-called installation effects, as induced by flow distortions that are found in realistic ducting environments.

Aerodynamic measurements include total-static pressure probes, hot wire anemometry, Laser Doppler Velocimetry, Stereoscopic Particle Image Velocimetry. Acoustic measurements can be performed by means of free-field microphones and acoustic modal decomposition techniques for the ducted fan configurations.

Operating point:

• Delta Pressure = 0 to 2000 Pa

• Max. volume flow rate = 1 m³/s or 3600 m³/h

• Simultaneous free-field acoustic measurements (cut-off 150 Hz

Anechoic certification :

Norm ISO3745

Mass flow rate measurements : Norms NBN722 and ISO5167

Two types of test benches :

1. Multi-port test bench for ducted systems

• ‘Infinite-duct’ qualification of blowers and other singularities -> test rig-decontaminated cross-validation w/ simulation

• Investigation of realistic and controlled installation effects -> better integrated design and mitigation spurious noise

2. Un-ducted fan test rig

• Modular mock-up (rotor, stator, HE …) -> source ID & installation effects

• Aeraulic performance test stand -> in-situ balancing and performance characterization]