The RC-1 facility is conceived to make detailed optical measurements of the relative flow in rotating channels. It allows aero-thermal evaluations of the flow in Micro Gas Turbine centrifugal compressor impellers or High Pressure Turbine internal cooling channels i.e. flows characterized by low Reynolds number, strong Coriolis forces, considerable heat transfer and wall roughness.

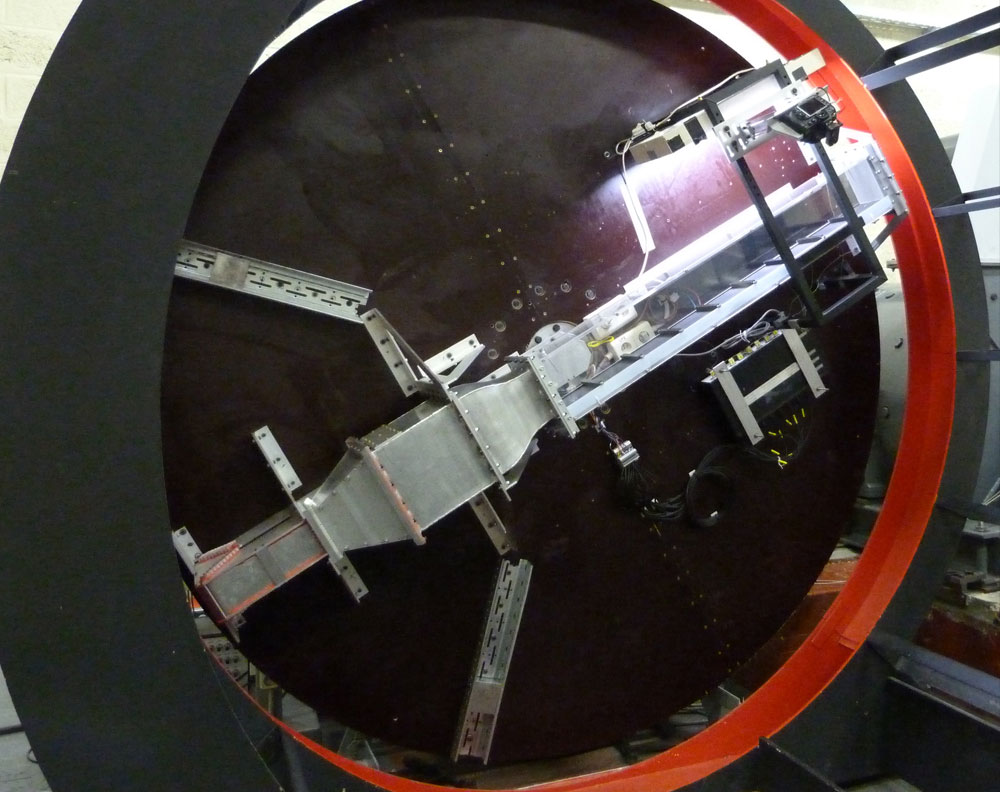

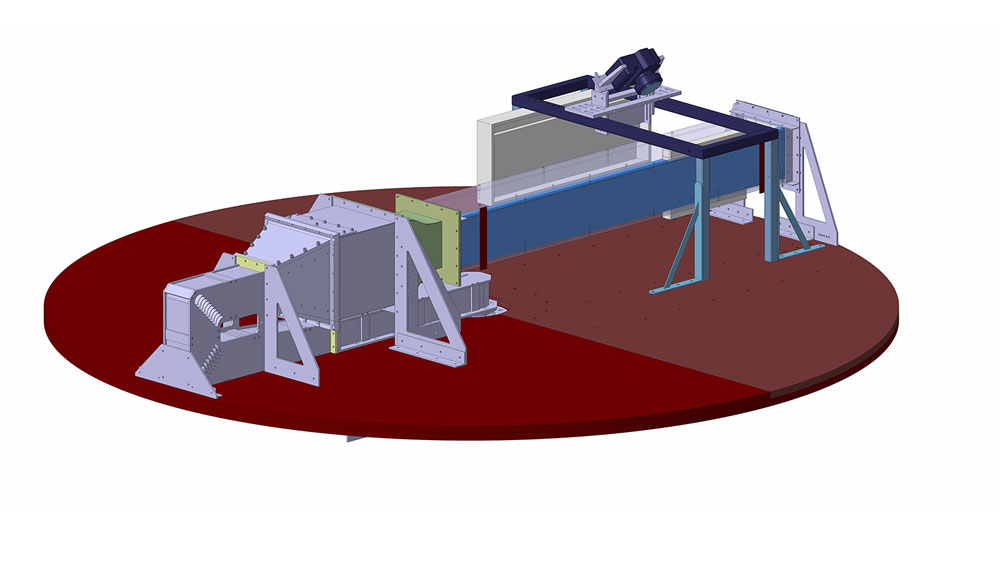

The test section of maximum 1m length and inlet hydraulic diameter of 0.079m. is mounted on a vertical rotating disk of 2.5 m diameter and maximum rotational speed of 160 rpm. The mass flow for stationary measurements is adjusted by means of a centrifugal blower. A throttling valve is used when rotation provides more than the requested mass flow. Electrical power and triggering signals are passed to the rotating disk by a 10 channel slip-ring.

Accurate time series of 2D relative velocity vectors fields are recorded by means of a Particle Image Velocimetry system fixed on the rotating disk. The light of a compact laser diode is transmitted to the measurement location by fiber optics. Images are stored during rotation in the 1 GB internal memory of the high speed camera. Indium Tin Oxide layers can be used to heat the channel walls up to 80°C, preserving optical access as well as a high signal-to-noise ratio. Heat transfer measurements by means of Liquid Crystals or an IR camera can provide detailed local heat transfer coefficient distributions in rotation.

Maximum Length: 1 m

Hydraulic diameter: 0.079 m

Vertical Rotating Disc: 2.5 m

Maximum Rotational Speed: 160 rpm

Fabrizio Fontaneto – Professor in turbomachinery and Propulsion Department

fabrizio.fontaneto@vki.ac.be