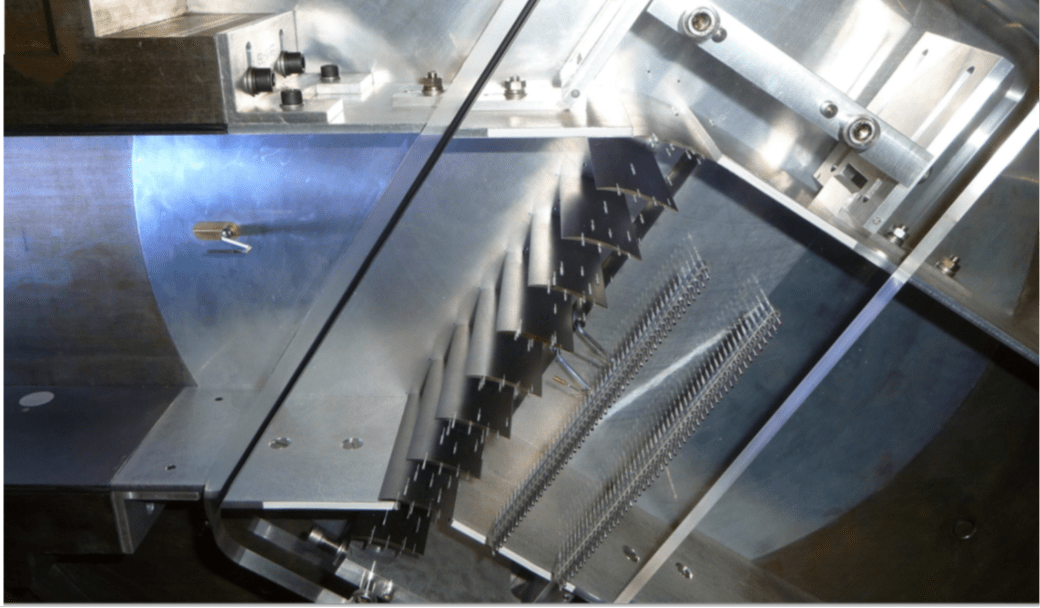

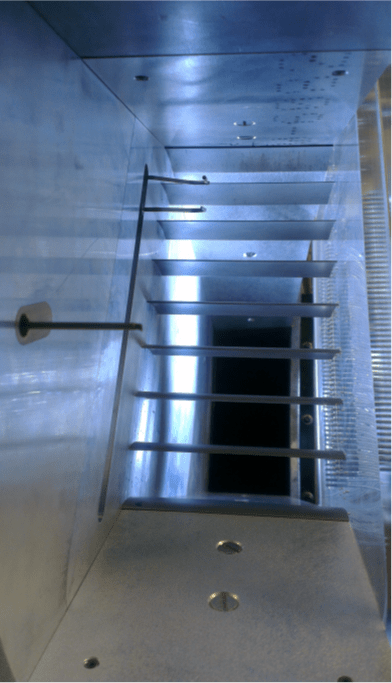

The high-speed wind tunnel C-3 is a blow-down facility with discharge to atmosphere and maximum exit Mach numbers up to M = 2.0. This test bench is mainly used for research on the high-speed aerodynamics of compressor and turbine cascades. The rig allows the installation of either linear cascades or annular sectors. Typical dimensions of the inlet section for a linear cascade configuration are 100 mm x 200 mm.

The rig settling chamber is fed by compressed air from a 72 m3 tank initially pressurized to about 35-40 bars at ambient temperature. A control valve between the tank and the settling chamber is continuously operated to keep the Mach number in the test section constant. The duration of a test run is in the order of 5-10 minutes depending on the test massflow. The settling chamber is equipped with screens and honeycombs to make the inlet flow to the test section uniform and to regulate the free-stream turbulence levels. The inlet angle can be changed continuously by rotating the test section.

Standard measurement techniques applied to the rig include endwall pressure taps, blade surface pressure taps, total pressure and directional probes coupled to fast traversing systems, large optical access for application of flow visualization, schlieren imagery, holographic interferometry and PIV techniques.

Reynolds range 500,000 – 2,000,000

Mach range 0.2 – 2.0

Max temperature 300 K

Max pressure 5 bars

Max rotating speed NA

Sergio Lavagnoli – Professor in turbomachinery and Propulsion Department

sergio.lavagnoli@vki.ac.be

Fabrizio Fontaneto – Professor in turbomachinery and Propulsion Department

fabrizio.fontaneto@vki.ac.be