The S-1/C wind tunnel is world-class turbine rig for testing large-scale, transonic, low-Reynolds number linear cascades.

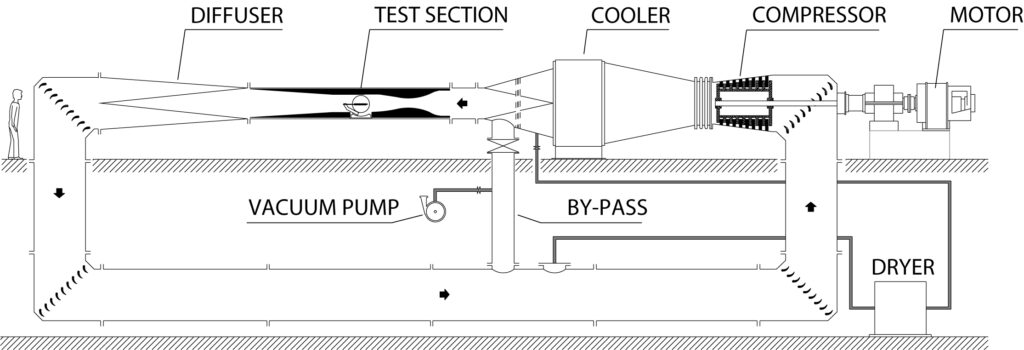

This test bench is a continuous closed-circuit facility driven by a 615 kW axial flow compressor. A water/air cooler allows controlling the flow temperature at near atmospheric condition and dry air is maintained at all conditions. The mass flow is regulated by the compressor rotational speed and a by-pass valve. A vacuum pump allows lowering the tunnel absolute pressure to ~ 8,000 Pascal. This wind tunnel was originally used for external aerodynamics applications such as the study of laminar shock boundary layer interactions and various supersonic flow configurations installed in a converging/diverging test section. It can be converted into a high-speed, low-Reynolds number turbomachinery cascade rig by removing the converging/diverging test section and replacing the downstream elbow of the circuit by a large linear cascade test section.

The test section can fit a large-scale turbine cascade model; the upstream channel height can be adjusted between 375 and 650 mm whereas the maximum airfoil span is 225 mm; typical chord lengths can be as high as 80 mm. This guarantees a sufficiently high aspect ratio, even for transonic exit conditions and high turning. The linear cascade ensemble is made up of several blades (at least 10) and the two large circular sidewalls (1,120 mm diameter) allow a continuous adjustment of the inlet flow angle. Upstream passive grids are used to control the background turbulence intensity.

The upstream part of the test section is equipped with a high-speed rotating bar system composed of a disc of 625 mm diameter, driven by an electric motor of 30 kW spinning up to 3,500 rpm, and mounting up to 96 cylindrical bars made of molybdenum. The number, diameter and rotational speed of the bars can be adjusted to generate engine-like rotor wakes in terms of wake frequency and velocity triangles, as opposed to low-speed systems using a linear bar displacement. The integration of both turbulence generation mechanisms allows reaching the expected turbulence and wake patterns observed in aircraft low-pressure turbines.

The facility allows investigating the aerodynamics of high-speed low-pressure turbines for direct-driven or geared turbofan engines at correctly scaled engine conditions (Mach and Reynolds numbers). A wide range of engine operating regimes can be set, from sea-level take-off to high-altitude cruising: The exit Reynolds and Mach numbers can typically be varied between 20,000 and 300,000 (depending on the blade chord length) and 0.6 to 1.2 respectively.

Recently, the S-1/C rig has been upgraded with an injection/suction cavity system integrated underneath the cascade inner endwall and with upstream rotating bars to study the combined effects of purge/leakage flows and periodic wakes on the 3D unsteady flow of a transonic LP turbine cascade.

The wind tunnel is equipped to monitor the operating conditions and several measurement techniques allow a detailed time averaged and time resolved blade wall behavior and global performance definition.

The cascade inlet and outlet flows are surveyed at multiple planes using pneumatic wall static pressure taps, multi-hole pneumatic pressure probes, thermocouple sensors as well as miniature fast-response directional probes and hot-wires. The various probes can be displaced in pitch- and span-wise directions across multiple cascade pitches by means of accurate traversing mechanisms. The central blade of the cascade and the inner endwalls are alternatively instrumented with surface pneumatic pressure taps, fast-response pressure sensors and hot-film gauges to measure time-resolved blade velocity and pseudo shear stress distributions. To enable fast scans of the 3D blade aerodynamics, the central instrumented blade, equipped with one stream-wise series of pressure sensors or hot films, can be displaced along the span-wise direction by means of a bespoke traversing mechanism.

Reynolds range : 20,000 – 300,000

Mach range : 0.6 – 1.2

Max temperature : 330 K

Max pressure : 1 bar

Max rotating speed : 3,500 rpm (wake generator)

Measurement instruments2 On wall and traversing pneumatic and fast response total, static and directional pressure probes. Hot wire anemometry. Thermocouples. Hot films.

Comment

PropComb Variable Mach and Reynolds number continuous cascade wind tunnel for low

pressure turbine airfoils. Test section cross-section: 225 mm x 650 mm. Aerothermal

performance determination (possibly time-resolved). Low pressure turbine

aero-engine similarity conditions (low – cruise – Reynolds number, high subsonic

Mach number). Periodic inlet wake simulation.

Instrumentation

The wind tunnel is equipped to monitor the operating conditions and several measurement techniques allow a detailed time averaged and time resolved blade wall behavior and global performance definition.

The cascade inlet and outlet flows are surveyed at multiple planes using pneumatic wall static pressure taps, multi-hole pneumatic pressure probes, thermocouple sensors as well as miniature fast-response directional probes and hot-wires. The various probes can be displaced in pitch- and span-wise directions across multiple cascade pitches by means of accurate traversing mechanisms. The central blade of the cascade and the inner endwalls are alternatively instrumented with surface pneumatic pressure taps, fast-response pressure sensors and hot-film gauges to measure time-resolved blade velocity and pseudo shear stress distributions. To enable fast scans of the 3D blade aerodynamics, the central instrumented blade, equipped with one stream-wise series of pressure sensors or hot films, can be displaced along the span-wise direction by means of a bespoke traversing mechanism.

Sergio Lavagnoli – Professor in turbomachinery and Propulsion Department